Hoses and hose assemblies are vital to the hydraulic system and must be regularly inspected and monitored for signs of wear resulting in hydraulic hose failure which limit machine operation & performance quickly. Komatsu genuine hose assemblies are specifically engineered and tested to work as a complete system lowering operating costs and helping to reduce downtime.

Why Purchase a Genuine Komatsu Hose?

- SAFETY BENEFITS. Superior quality hoses result in a lower safety risk while a non-genuine hose becomes a higher risk.

- REDUCED DOWNTIME. OEM-engineered to the highest standards can limit the risk of unplanned down time.

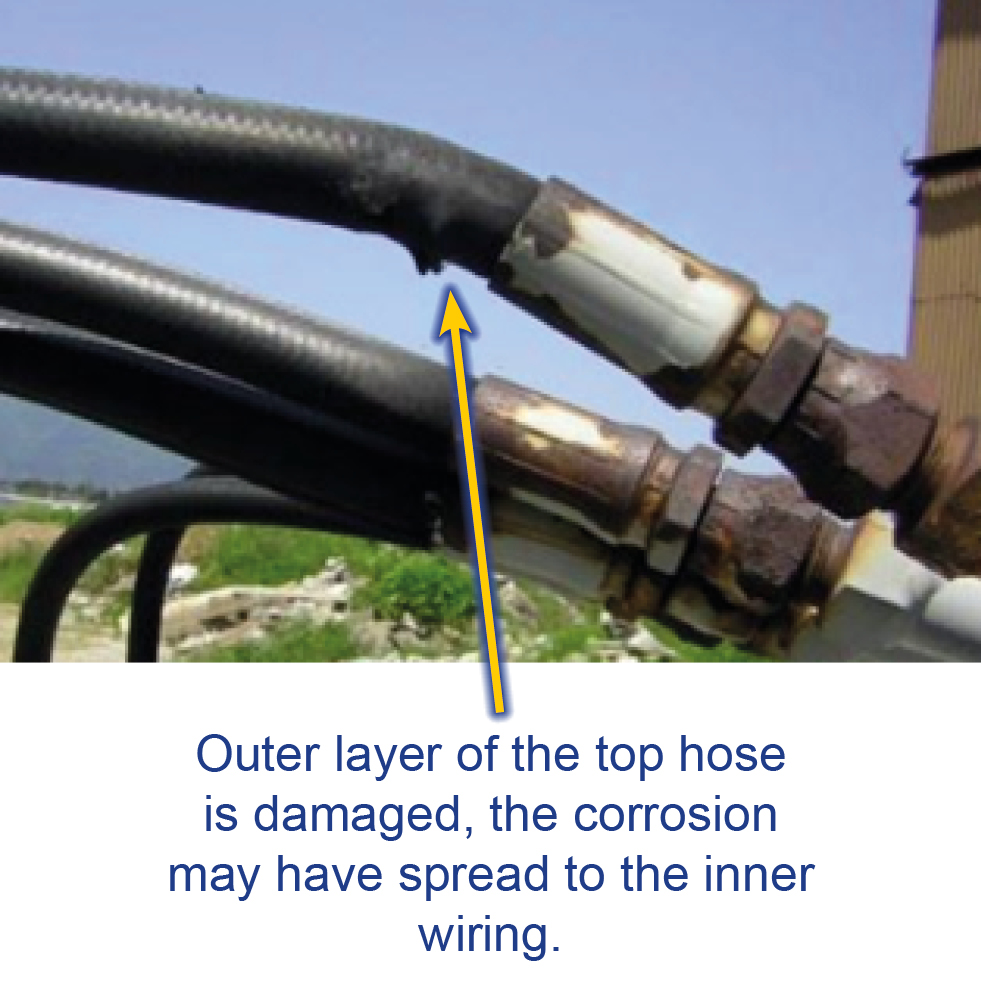

- SUPERIOR HARDNESS & DEPTH. Superior Hardness & Depth – The outer section of a genuine hose has anti-abrasion and flame-resistant qualities.

- OEM QUALITY PRODUCT. OEM Quality Product – Komatsu Engineering Standard (KES) requires higher quality than that of commercially available hoses.

Genuine Hose Assemblies

Fluid and Environment Hose Temperature Rating – Genuine Hoses have the correct hose temperature rating to provide the necessary range performance to boost the overall lifetime of the hose.

Fluid-Hose Compatibility – Genuine Hose assemblies will have the correct inner tube material to provide the necessary fluid compatibility to help preserve the lifetime of the hose.

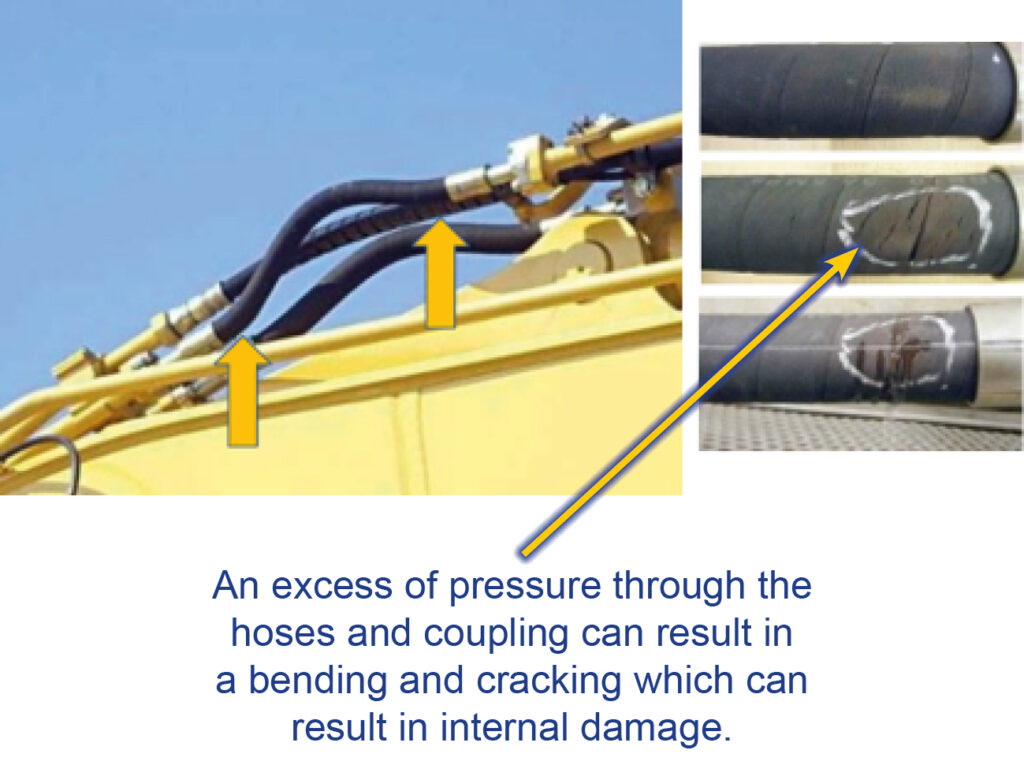

System Pressure – Selection and qualification of Genuine Hoses and Hose fittings are based upon system pressure specifications to avoid safety and quality issues such as bursting or loosened fittings.

ISO Standards – Genuine Hoses follows ISO/TS 17165-2 International standards and additional KES (Komatsu Engineering Standards) to ensure safe, reliable, and long-lasting products.

Couplings

Genuine Komatsu Hoses are designed with a variety of couplings:

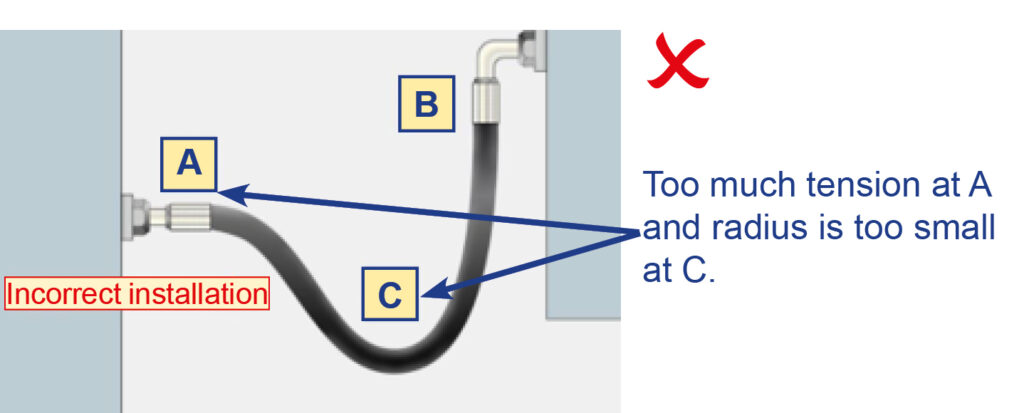

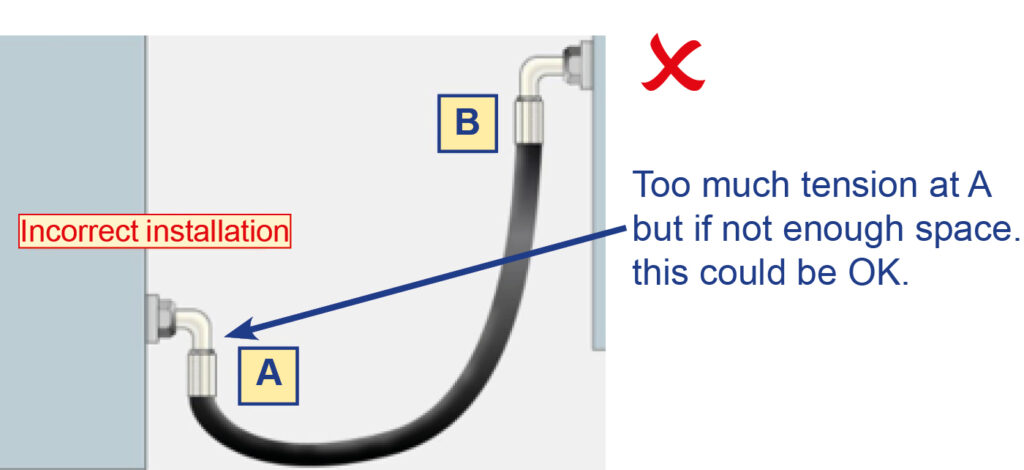

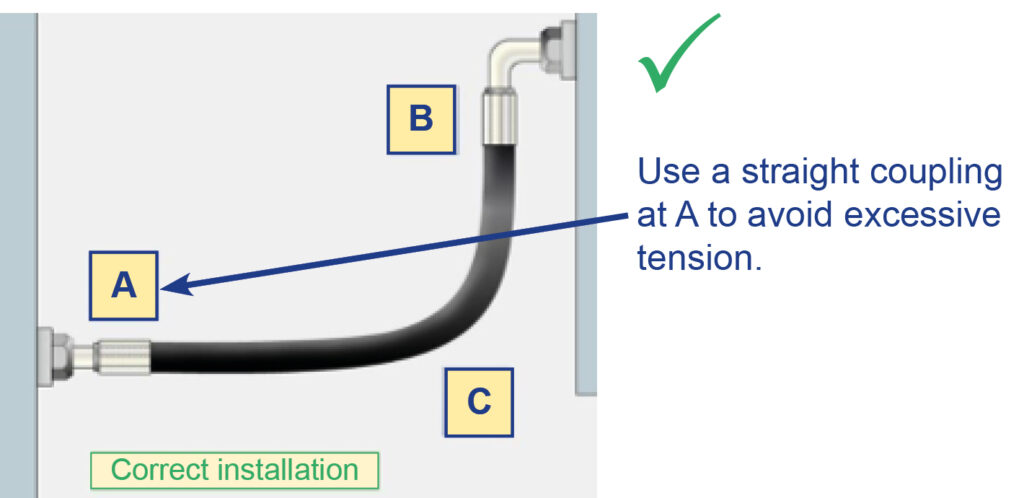

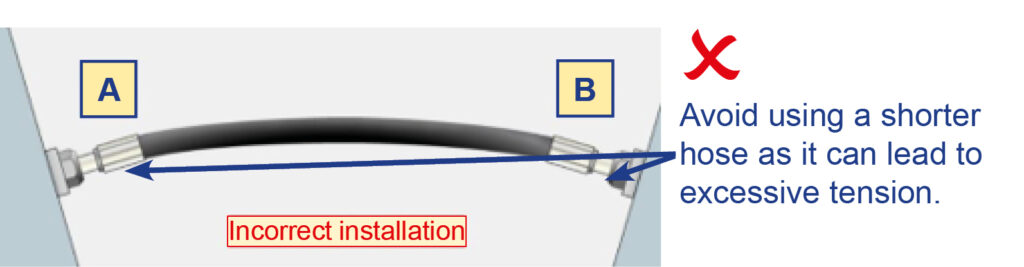

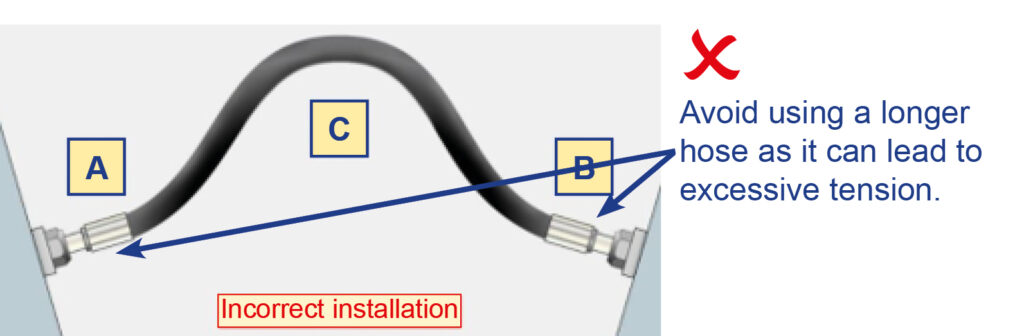

Installation Tips

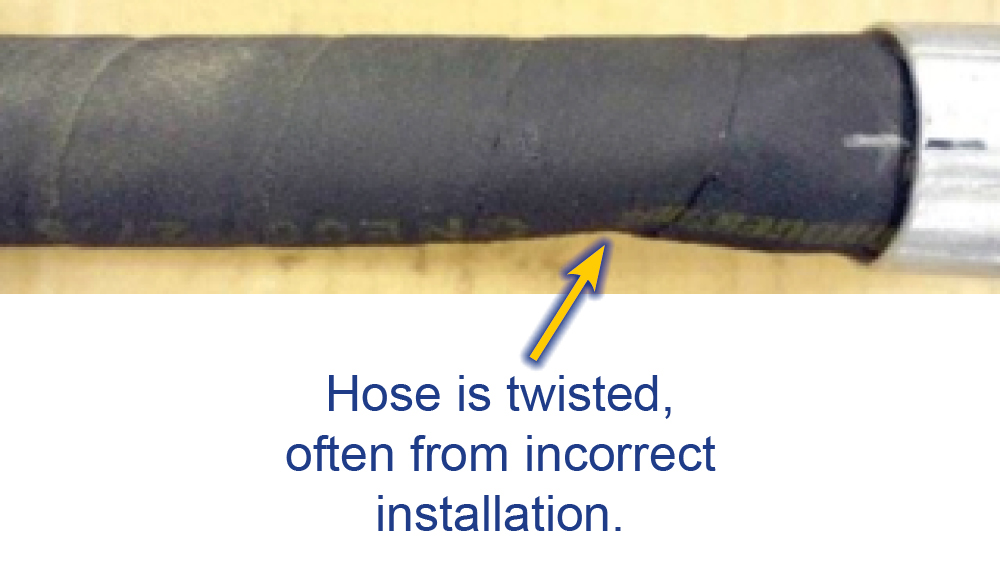

Examples of damaged hoses

The visual checking of a machine’s hydraulic hoses should be customary when performing your pre-shift walkaround inspection

Genuine Komatsu Hoses and Hose Assemblies are available off-the-shelf for the majority of machines.

Contact our parts line today on 0845 601 5540 or [email protected]