Marubeni-Komatsu Ltd. is committed to maximising the potential of your machine, which is why we offer the most advanced and most reliable parts to optimise performance and to reduce operating costs. The Undercarriage PLUS system is another example of this commitment.

With new rotating bushings and other key enhancements, Komatsu designed the Parallel Link Undercarriage System (PLUS) to increase wear life, reduce machine downtime and to lower repair & maintenance costs.

Komatsu Undercarriage PLUS can be fitted to new Komatsu dozers but PLUS can also be retrofitted. To convert from standard undercarriage to PLUS, the following parts need to be replaced:

• Track Link Assembly

• Track Shoes

• Shoe Bolts & Nuts

• Track Guard (if fitted)

• Sprocket segments

• Track Rollers

• Carrier Rollers

ENQUIRE NOW

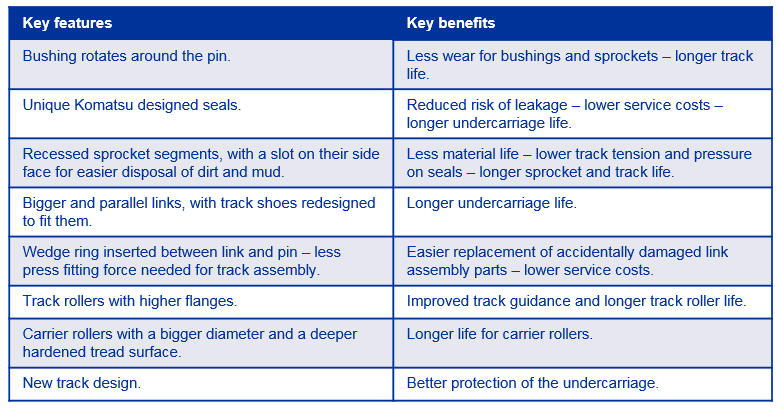

What makes Undercarriage PLUS special?

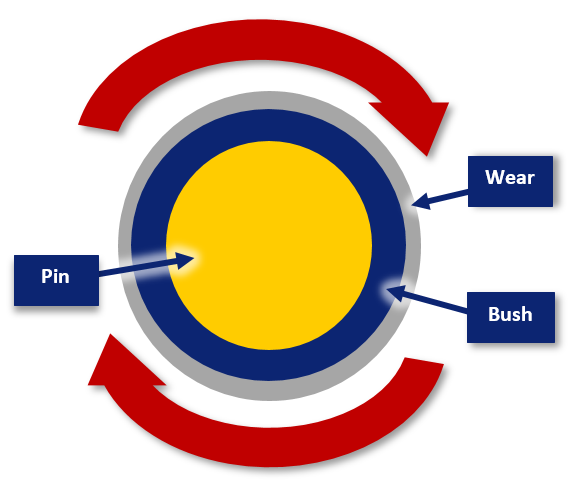

Rotating bushings eliminate cost and downtime by ensuring that the whole bush component surface is worn rather than just two sides.

Undercarriage PLUS bushing

Equal wear distribution around entire revolving & rotating bushing surface causes a slower wear ratio.

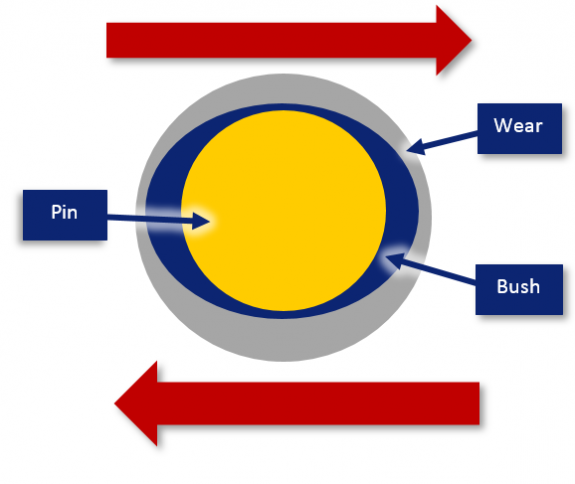

Standard bushing

Continual wear along 2 sides of the bushing surface increases wear quicker.

The evenly distributed wear around the entire surface of the rotating bushing prolongs the life of the sprocket, track links and rollers with undercarriages lasting up to 6000-hours and sometimes beyond before needing to be replaced.

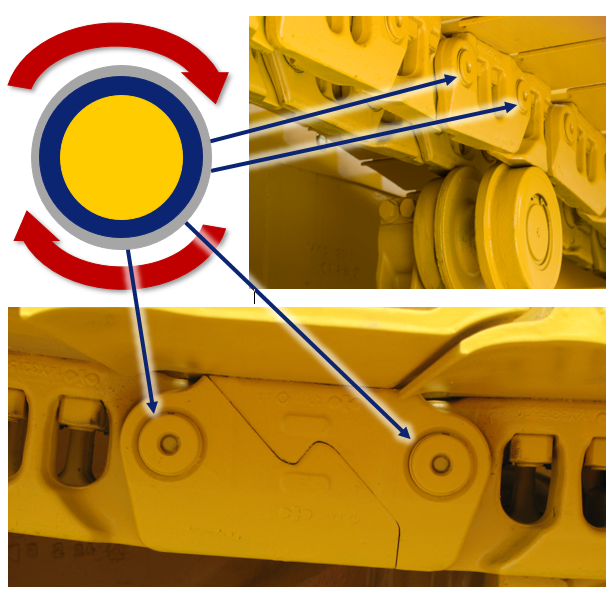

Where to find the rotating bushing

The rotating bush is not the only modification that Undercarriage PLUS offers:

Sprockets

– Newly design recessed sprockets to avoid material packing which could cause too high pressure on the track link assembly seals.

Undercarriage PLUS sprockets

Standard sprockets

Track rollers

– A new track roller design improves the track guidance, and is designed and manufactured to last as long as the rest of your PLUS undercarriage.

New track roller (single flanged)

New track roller (double flanged)

Innovative crocodile links

The Undercarriage PLUS crocodile link design makes it very easy to split the tracks if access is ever needed to other components such as the Track Spring/Idler Cushion. Avoids the needs to remove the entire track chain.

Marubeni-Komatsu Ltd. customer experiences with undercarriage PLUS.

South Lanarkshire-based Plant Hire company Ward Plant Ltd has just replaced the Undercarriage PLUS on his D61 dozer after nearly 7000-hours. Ward Plant Ltd went with Undercarriage PLUS again, changing only the track group and sprockets as the original rollers were still going strong.

Telford-based Plant Hire company Stokey Plant Hire saw the benefit of investing in Undercarriage PLUS on their two D65 dozers and saw both undercarriage systems lasted 6000 hours before needing to replace them.

Any customer hiring a Komatsu machine from Stokey Plant Hire or Ward Plant Ltd companies are sure to receive a reliable, high-quality machine that won’t quit in the harshest conditions.

Komatsu undercarriage field tests

Komatsu recently ran several field tests to challenge the versatility and durability of both conventional undercarriage and undercarriage PLUS in different applications.

Disclaimer – field test results will vary depending on terrain type, weather, job application and operator’s driving

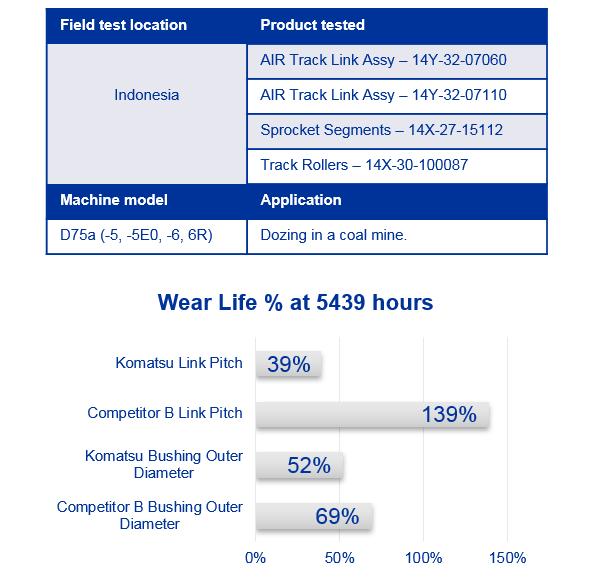

Test results

• Competitor B: Link Pitch wear was 139%. The track chain had to be replaced because it was too elongated (due to internal pin & bushing wear). Bushing wear was 69%.

• Komatsu: Link Pitch wear was 39%. Bushing wear was 52%.

Conclusion

Komatsu Track Life is 1.9 times longer than Competitor B.

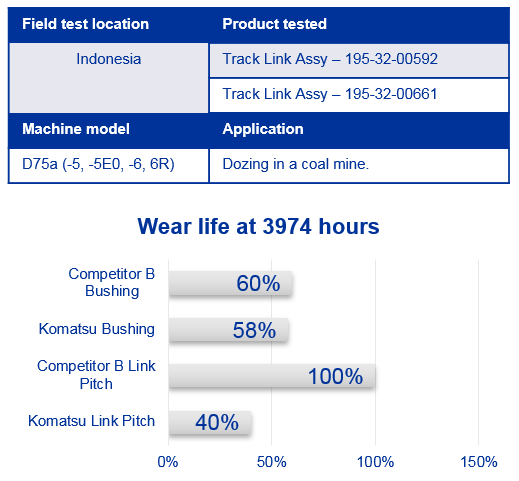

Test results

• Competitor B: Link Pitch wear was 100%. The train chain had to be replaced because it was too elongated (due to internal pin & bushing wear). Bushing wear was 60%.

• Komatsu: Link Pitch wear was 40%. Bushing wear was 58%.

Conclusion

Komatsu Track Life is 1.7 times longer than Competitor.

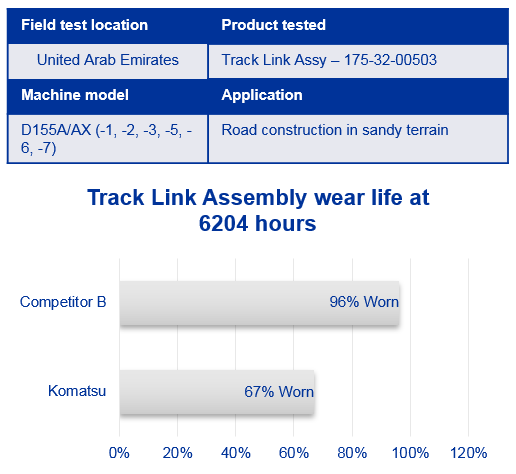

Test results

• Competitor B: Link Pitch wear was 100%. The train chain had to be replaced because it was too elongated (due to internal pin & bushing wear). Bushing wear was 60%.

• Komatsu: Link Pitch wear was 40%. Bushing wear was 58%.

Conclusion

Komatsu Track Life is 1.7 times longer than Competitor.

Packing

The PLUS undercarriage excels in almost every application and environment, even in dense packing material.

Warning: Make sure you regularly clean the undercarriage as constant clogging and packing will have an adverse impact on the quality of the undercarriage. This applies to any undercarriage system.