Handling and storing your machines oils correctly doesn’t only ensure your safety but it also avoids contamination and helps them to last longer.

In this article we will cover the correct storing and handling methods for the following:

-

- Oils

- Fuel

- Coolant/Antifreeze

- AdBlue®

Guidelines for handling and storing oils

When changing the oil or adding the oil, do not mix different types of oil. When changing the type of oil, drain all traces of the old oil and fill completely with the new. Always replace the filter at the same time.

Oil is used in the engine and hydraulic equipment under extremely severe conditions (high temperature, high pressure) but deteriorates with use. Always use oil that matches the grade and maximum & minimum ambient temperatures recommended in the Operation & Maintenance manual. Even if the oil is not dirty, always change the oil at the at the specified interval.

Always be careful when handling oil to prevent impurities or contaminates from getting into it. Most engine failures are caused by contaminated oil. Special care should be taken when storing or adding oil.

Never mix oils of different brands or grades.

Always add the specified amount of oil. Having too much oil or too little oil are both causes of failure.

If the oil in the work equipment is not clear, there is probably water or air getting into the circuit. In such cases, consult your local Komatsu depot.

When changing the oil, always replace the related the filters at the same time.

Guidelines for handling and storing coolant/antifreeze

Fuel

To prevent the moisture in the air from condensation and forming water inside the fuel tank, always fill the fuel tank after completing the day’s work.

The fuel pump is a precision instrument, and if fuel containing water or dirt, it cannot work effectively.

Be extremely careful not to let impurities get in when storing or adding fuel.

Consult the operations manual for advice on storing fuels, as storing in too hot an environment will cause viscosity to drop effecting output. Storing the fuel in too cold an environment and it will solidify and clog.

Before starting the engine, or after 10 minutes of adding fuel, drain the sediment and water from the fuel tank.

If the engine runs out of fuel, or if the filters are replaced, it is necessary to bleed the air from the circuit.

If there is any foreign material in the fuel tank, wash the tank and fuel system completely.

Coolant/Antifreeze

The coolant has the important function of preventing corrosion as well as preventing freezing is not an issue, the use of coolant is essential.

When using antifreeze, always observe the precautions given in Operations & Maintenance Manual.

If the engine overheats, wait for the engine to cool before adding coolant.

If the coolant level is low, it will cause overheating

Guidelines for handling and storing AdBlue®

What is AdBlue®?

Adblue® is a liquid that consists of 32.5% of urea and 67.5% of distilled water. Despite the name, the liquid is colourless.

Komatsu EU stage IV engines use Adblue® in combination with the Selective Catalytic Reduction (SCR) technology which reduces emissions. The SCR NOx reduction system injects the correct amount of Adblue® at a precise rate, thereby decomposing NOx into non-toxic water and nitrogen gas.

Handling Adblue®

If AdBlue® gets onto your skin, it may cause inflammation. Immediately remove contaminated clothing or shoes and wash with water. In addition, use soap to wash it off thoroughly, if your skin becomes irritated or begins to hurt, immediately consult your doctor.

If AdBlue® is swallowed, do not induce vomiting. If swallowed, rinse mouth thoroughly with clean water for several minutes. Consult doctor for treatment.

Avoid contact with eyes. If there is contact, flush with clean water for several minutes and consult doctor for treatment.

Wear protective eyeglasses such as goggles when exposed to AdBlue® to deflect any splashing. Wear rubber gloves when you perform work handling AdBlue® to avoid skin contact.

Protect yourself from escaping ammonia vapour when opening the AdBlue® tank by keeping your face away from the filler port.

Adblue® Storage

Completely seal the AdBlue® container for storage. Only open containers in a well-ventilated area.

Avoid storing AdBlue® in direct sunlight.

Always use the original container.

Make sure that transfer equipment and tank meet AdBlue® compatible material specification. If AdBlue® is stored in an iron or aluminium container, toxic gas may escape and a chemical reaction may corrode the container.

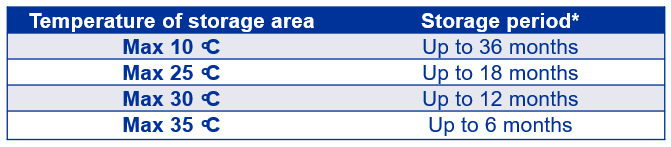

Please use this table to predict the recommended storage period based on temperature:

*Do not store AdBlue® at 35 ͦC or above

- If you must use another container, please clean container and ensure it is made of either polyethylene or stainless steel.

- When disposing of AdBlue®, it should be treated as industrial waste. The container for AdBlue® is also classed as industrial waste. It should be treated in the same manner.