In a competitive industry such as Plant Hire, it’s important to stay one step ahead of the game and not be persuaded to buy cheap systems or components in the short term as you soon realise that you are spending twice or three times over on replacement parts in the long term. Komatsu’s Undercarriage PLUS can last up to 6000-hours and, if taken care of, often longer.

Customers need to be confident and reassured when they are hiring a machine that it will be reliable and won’t fail as million-pound projects & deadlines depend on it.

South Lanarkshire based Ward Plant and Telford based Stokey Plant Hire both have reputations to uphold and with nearly 100 years-experience in the plant hire, earthmoving and material handling industry, they both recognised the need to invest in a high quality, long-term undercarriage solution.

They both, like many others, opted for Undercarriage PLUS. Here’s why…

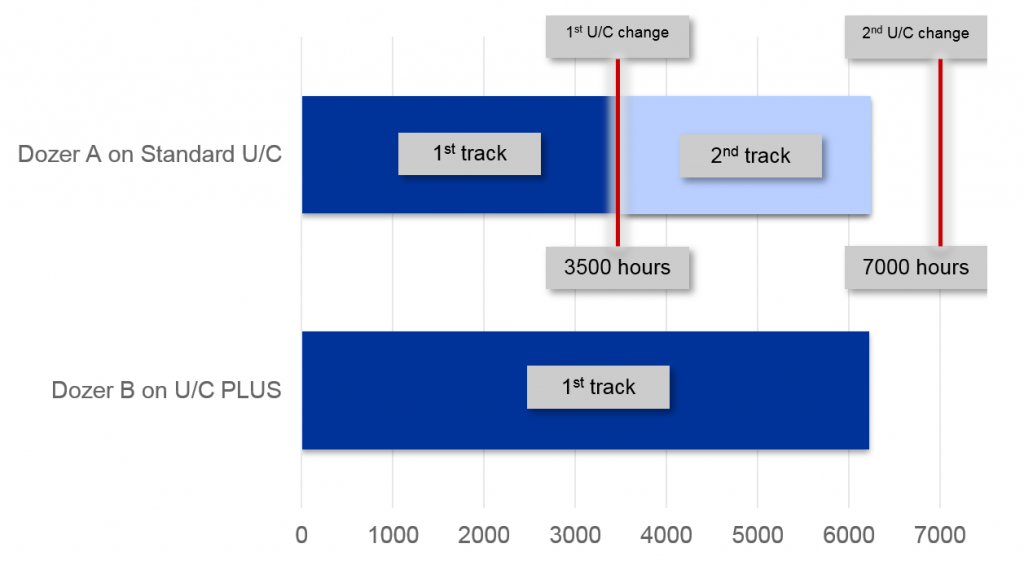

Standard Undercarriage is generally expected to last approximately 3500-hours so at 6224-hours, as in Stokey Plant’s case, for a dozer’s undercarriage to still be operational after 100% wear is impressive. As you can see from the Undercarriage Inspection reports below, the Undercarriage PLUS on both Ward Plant & Stokey Plant machines were fully operational after 7000 and 6000 hours respectively. A conservative estimate would predict that a dozer operating on standard undercarriage at 6224-hours, the wear would be over 200% or destroyed due to excessive use.

ENQUIRE NOW

In the time it takes Undercarriage PLUS to reach 6224-hours, Dozer A on Standard Undercarriage is close to being on its 3rd set of standard tracks. That’s 3 times the expenditure on Standard U/C compared to a single purchase of U/C PLUS.

Example of machine undercarriage life at 6224 hours:

Hours worked

Customers results:

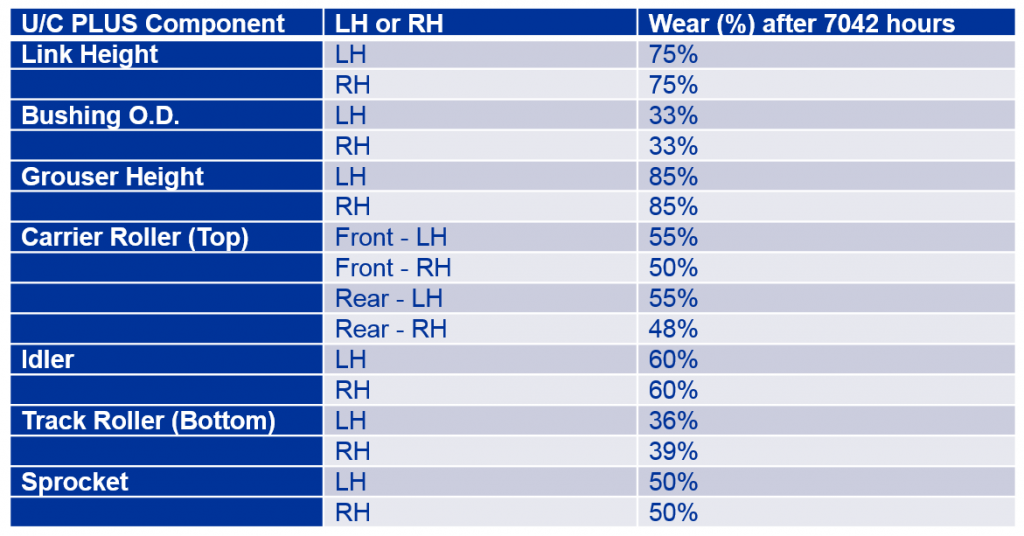

Ward Plant Ltd.

D61PX-15 Undercarriage PLUS at 7042 hours

Undercarriage inspection report:

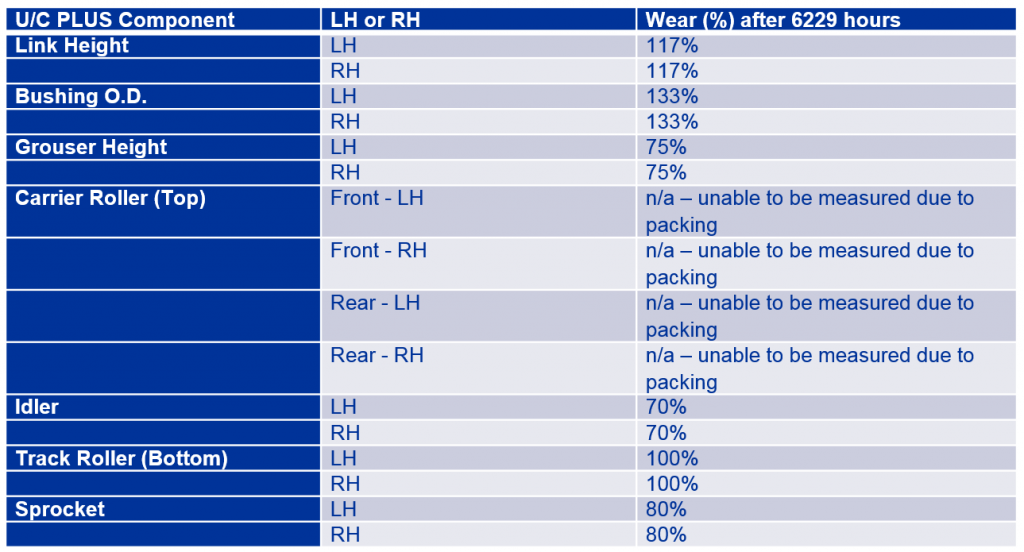

Stokey Plant Ltd.

D65PX-17 Undercarriage PLUS at 6229 hours

Undercarriage inspection report: