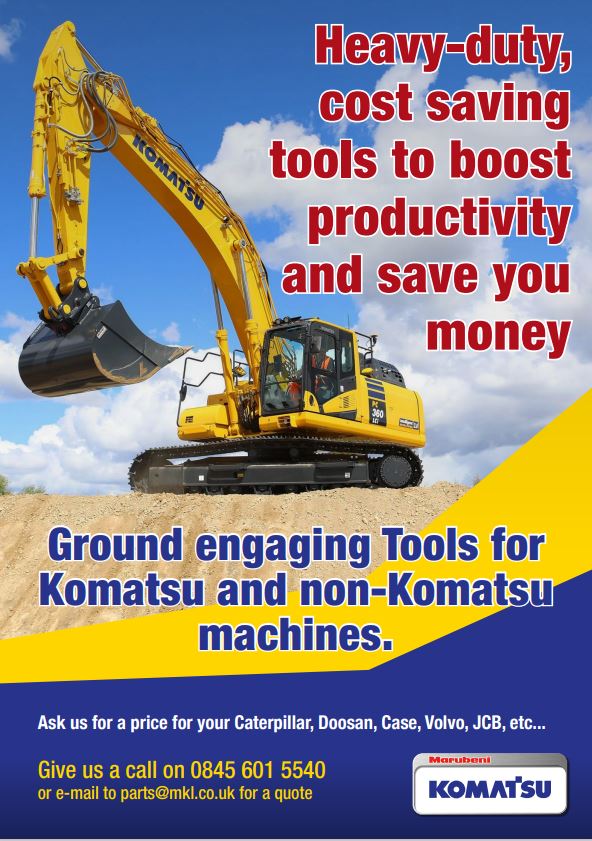

Marubeni-Komatsu offers genuine ground engaging tools solutions from the smallest utility machines to the world’s large production machines, we have a solution for any application and any make/model of machine. Available components include teeth, blades, buckets and wear parts.

Bucket inspection programs

Arrange a comprehensive inspection of your machine’s bucket to ensure maximum productivity, penetration and cost per hour. Prevent large-scale damage by highlighting potential risks in your application.

Bladesaver QM

Fully integrated 100% lip protection system for wheel loaders. A streamlined profile for reduced base lip wear. Hammerless tooth and shrouds for quick, easy and safe changes out in the field.

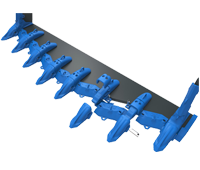

Tooth systems

High quality tooth systems such as Kprime, KVX and Dura available for most makes & models. Safe and hammerless systems for quick change-outs and less machine downtime. Heat treated to 500 Brinell for exceptional hardness, strength and durability. A reversible tooth shape and a fastener that can be re-used multiple times ensure excellent value for money.

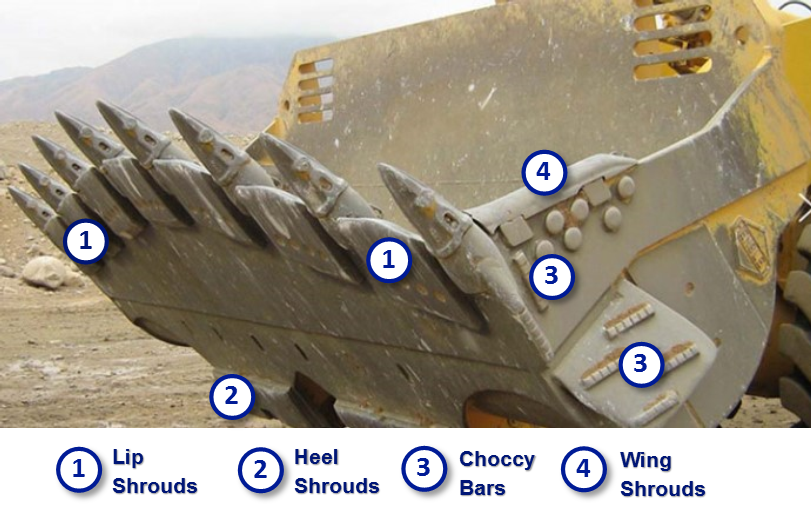

Wear products

Multiple styles and sizes to fit most makes and models. Designed to provide strategic protection for your bucket to cope with the rigours of your application. Lip, heel and wing protection for excavators and loading shovels such as choccy bars and buttons. Heated to exceptional hardness for maximum protection.

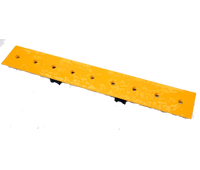

Cutting edges and end bits

Suitable for dozers of all makes/models, Marubeni-Komatsu offers a range of heavy-duty cutting edges and end bits heated to 500 Brinell for maximum wear life. Highly durable and abrasion resistant, uniquely designed to be reversible for double the wear life.

Heavy duty blades

An extensive range of blades suitable for all makes & models of Wheel Loader. Heat treated to 500 Brinell, these blades offer superior strength and longevity.

Hydraulic breakers

The Komatsu JTHB hydraulic breaker range delivers exceptional impact energy, long lifetimes and low operating costs. What’s more, they minimise operator fatigue and environmental impact.

Pulveriser & Crusher

These reliable attachments are designed to meet the customer’s needs for efficiency, performance and reliability.

Sorting Grapples

The Komatsu JRSG Sorting and Demolition grapple range come as standard with a load control valve, oversized pins and bushings, a robust double-walled main frame and perforated Hardox shells.

Bucket wear product locations:

Wheel Loader bucket

Excavator bucket

Kprime Tooth System

Kprime is a revolutionary new tooth system with has been designed with improved safety features to lower the risks of accidents on site – such as an easy-to-remove quarter turn with a metric socket for removal and an audible ‘clack’ to signify when the pin is locked. The Kprime tooth has up to 15% more usable wear material than its predecessor with a redesigned inner core for a stronger, more stable fit for increased reliability and a longer-lasting tooth.

For added value, the Kprime can be rotated on the adapter for an increased lifetime, and designed to stay in a pointed shape so that the integrity of the tooth is not lost over time.

Marubeni Komatsu is constantly improving its core range of Ground Engaging Tools to provide the best quality, most cost-effective and productive parts on the market to match all applications.

Tony Bull – G.E.T. Specialist

With 30 years in the construction industry focused on Ground Engaging Tools, Tony Bull is Marubeni-Komatsu’s G.E.T. specialist and is on hand to answer any queries you may have.

Call Tony on: 07917017413